The primary ingredient of beer is malted barley. Barley for English brewing is traditionally a specially selected variety of English two-rowed barley. English brewing barley is usually specially grown, because it is important that brewing barley should have a low protein content. An excess of protein and certain other nitrogenous substances will encourage haze to be formed in the finished beer.

The primary ingredient of beer is malted barley. Barley for English brewing is traditionally a specially selected variety of English two-rowed barley. English brewing barley is usually specially grown, because it is important that brewing barley should have a low protein content. An excess of protein and certain other nitrogenous substances will encourage haze to be formed in the finished beer.

Read also:

Home Brewing. What should You Know about the Hops

Traditional Commercial Brewing

Home Brewing. Beginners Start Here

All You should Know about Brewery Yeast

Home Brewing. Water and Water Treatment

Home Brewing. Mashing and Sparging

The Barley

The primary ingredient of beer is malted barley. Barley for English brewing is traditionally a specially selected variety of English two-rowed barley. English brewing barley is usually specially grown, because it is important that brewing barley should have a low protein content. An excess of protein and certain other nitrogenous substances will encourage haze to be formed in the finished beer. Fortunately, the English climate, cultivation techniques, and strain of barley assists in the production of a low protein/nitrogen product. English brewing barley is usually grown at a lower density per acre than barley used for other purposes, and the use of nitrogen-based fertilisers is avoided.

The barley grain consists, essentially, of two parts: the inner part, called the endosperm, which is mostly starch; and the outer part, called the aieurone layer, which is a tough outer wall surrounding the endosperm and consists of a number of complex proteins. The starch contained in the endosperm is important because it is broken down during mashing into maltose to yield fermentable sugars and ultimately beer. The proteins contained in the aieurone layer are just as important because they are high molecular weight nitrogenous substances which are broken down during malting into simpler, soluble, low molecular weight nitrogenous substances, to yield amino acids, peptides, and most importantly, enzymes. The amino acids, peptides, and other forms of assimilable nitrogen are important to the yeast, but an excess of these will provide food tor bacteria during storage, the lactic acid bacteria in particular.

A good sample of barley suitable for brewing purposes should have a uniform grain size, a powdery endosperm, it should be of the proper colour, and, of course, the nitrogen level should be correct. Before a maltster buys barley he tests a sample to ensure that it meets his requirements and that it malts satisfactorily.

During the malting process a group of enzymes break down proteins in the outer wall of the barley (the aleurone layer) to render the starch contained in the endosperm open to attack. In the old days these enzymes were known collectively by the old-fashioned name of cytase, but, in a more modern vein, the two most important enzymes groups are known as proteases (proteinase), and peptideases (peptidase) and each group consists of a number of individual enzymes. The proteases (enzymes that attack protein) also degrade the small amount of protein which is comtained in the endosperm itself. This protein can be considered to be in the spaces between the starch molecules and acts as a binder. The degradation of these 'binding' proteins renderes the starch open to attack by other enzymes during the subsequent mashing process. The protein degradation is known as modification. A fully modified malt is one where as much of the starch and protein as possible has been degraded by the malting process and is typical of English malts. A poorly modified malt is one where some of this remains undegraded and was typical of German lager malts of over a hundred years ago, and requires special mashing techniques to complete the conversion. Modern lager malts are more fully modified than those of yesteryear and do not require the employment of special techniques to make use of them.

The maltster uses nitrogen content as a guide to the malting quality of his barley. The protein contained in the aleurone layer is a nitrogenous compound, therefore a barley which has a high nitrogen content will have a higher ratio of protein to starch than will a barley of low nitrogen content. The higher level of protein could give rise to hazes being formed in the beer, whereas the lower level of starch will provide a lower level of fermentable extract, making the malt less efficient. However, the important enzymes are also nitrogenous substances, therefore a barley which has a low nitrogen content would also have a low enzymic activity, which again may be undesirable.

The nitrogen content of barley and the nitrogen content of the resultant malt is very important, and must be held within certain limits if the correct balance of protein, starch, and enzymic activity is to be achieved. In general, barleys of differing nitrogen contents are used to make different types of malt. A high nitrogen malt would have a lower fermentable extract and a higher level of undesirable proteins than would a low nitrogen malt, but it would also have a high level of enzymic activity which is an advantage in some applications. The opposite would be true of a low nitrogen malt. In general, low and medium nitrogen barleys are used to make primary malts, whereas high nitrogen barleys are used to make coloured malts and some adjuncts.

Two other important enzymes are contained in our barley and ultimately in our malt; namely alpha-amylase and beta-amylase. These enzymes are not particularly active during malting, but are utilised during mashing and serve to break down the starch contained in the endosperm into sugars which will be fermented by the yeast. These two enzymes are known as diastatic enzymes. However, this brings us on to the diastatic power of malt.

The diastatic power of the malt is a measure of the quantity of the diastatic enzymes present in the malt and is therefore a measure of the speed at which starch is converted into sugars. Most malts have a quantity of diastatic enzymes surplus to requirements and these enzymes can be effectively used to convert the starch in other cereals into fermentable sugars. These cereals, such as torrefied barley, flaked barley, or wheat flour contain convertible starch but do not contain the diastatic enzymes necessary to effect conversion. These enzymes must be supplied by the malt. The higher the diastatic power of the malt the greater the quantity of these additional cereals it can convert. Highly diastatic malts can have a penalty; the diastatic enzymes are more abundant in high-nitrogen malts, and high-nitrogen malts will give a greater risk of haze formation and a lower fermentable yield.

The kilning stage of malt production dries the malt to well-defined levels of moisture content. The basic malts are dried at relatively low temperatures to preserve the diastatic enzymes that we require during our mashing stage, and the proteinase which is necessary for lager production in particular. Lager malt, pale malt, and mild ale malt are typically dried to 3.8, 3, and 2.8 per cent moisture content respectively and, of course, their colours are progressively darker.

Roasted malts such as chocolate malt or black malt are quickly dried at high temperatures, which destroys the enzymes but colours the malt accordingly. The range of malts are described here, listed in order of colour imparted, palest first:

Lager malt

Lager malts are kilned at low temperatures to provide a very pale colour, and to preserve a high level of enzymic activity. Traditionally, lager malts were poorly modified and required special mashing techniques in order to use them efficiently. Modem lager malts are fully modified and can safely be used in the traditional British single temperature infusion mash without problems. A modern lager malt should, in theory, have a high level of enzymic activity, particularly pro teinase, and can therefore be usefully employed in a temperature stepped mash to assist in the convertion of high levels of starchy adjuncts.

Pale malt

Pale Malt, as its name implies, is pale in colour. It is the basic ingredient of English pale ales and bitters, but finds application in almost any type of English beer. It is a fully modified malt that has been kilned at a low temperature for a long period, until its moisture content is about 3 pet cent. Pale malt has good diastolic activity and can be used to assist the conversion of a certain amount of non-diastatic cereal.

Mild ale malt

Mild ale matt is initially prepared in the same way as pale malt except that a higher nitrogen barley is used. It is kilned at a slightly higher temperature and for longer than pale mail to reduce its moisture content to about 2.8 per cent. As one would expect, mild ale malt is darker in colour than pate malt and has a slightly lower extract. Mild ale malt has a higher diastatic activity than pale malt, allowing a higher proportion of adjuncts to be used in the grist makeup. A higher level of adjuncts is typical of mild ale production and these provide the characteristic flavours of mild ale.

Munich malt

Munich malt is a darkish malt which, as its name implies, is traditionally used by the breweries of Munich in their darker beers. It has a fairly low level of diastatic activity; about half that of paler malts, and is not really suitable for using in conjunction with high levels of adjuncts. It is not likely to be found in British home-brew shops although it has been available in the past. There is no particular advantage to be gained from using it in preference to British malts, unless one is particularly trying to imitate a Munich beer.

Amber malt

Amber malt is prepared by rapidly heating fully-cured mild ale malt to about 100°C in a kiln, and then slowly allowing the temperature to rise up to a maximum of about 150°C. As soon as the malt has turned the correct colour it is allowed to cool. Amber malt has a characteristic biscuity taste and finds application in mild ales, brown ales, old ales, and some bitters. The high temperatures involved in its production destroys many of the enzymes, therefore amber malt has little diastatic activity but it does yield fermentable extract if mashed alongside a diastatic

Brown malt

Prior to the start of the pale ale revolution in about 1840 almost all beers were brown beers made from brown malt. Brown malt is a smoked malt, traditionally kilnes over a hardwood fire of oak, ash, beech, or hornbeam, apparently, being the most common. The origin of brown malt is probably synonymous with the origins of brewing in this country. The Celts were using grain drying kilns in this country long before the Romans popped across for a pint in 55 BC, and they would certainly have been wood fired.

Brown malt remained the most commonly used malt until the industrialisation of Britain provided cheap supplies of coal and coke in the early nineteenth century; at which point, pale malt, which was kilned over coal, coke or charcoal, became cheaper than brown.

All of the early ales and beers, brown ales and porter, would have had a rich smoky flavour derived from the brown malt. The term "brown" refers to the fact that the malt is smoked; its colour is a minor secondary effect. Even today, brown ales should technically be made from smoked malt, although few, if any, are. Some brown malt is still made these days but it is rare and unlikely to find its way into our home-brew shops. It is fairly straightforward to smoke malt with the appropriate equipment.

Crystal malt

Crystal malt, sometimes referred to as caramel malt, is prepared by wetting high nitrogen green malt (unkilnled), heating to 65°C in a closed vessel, and holding this temperature until the starch in the endosperm has been hydrolysed into a sugary syrup. The grains are then kilned at approximately 250°C which dries the malt, caramelises some of the sugar, and colours it to a light red-dish tint. When the grain has cooled it forms a solid sugary mass. Crystal malt is a very common ingredient in English-style bitters and it imparts a distinctive nutty flavour. Crystal malt contains a high proportion of dextrins and other non fermentable sugars and it will therefore provide a degree of body in the finished beer.

Crystal malt has had its starch converted to sugars during manufacture and does not need to be mashed during the brewing process. In grain brewing (as opposed to malt extract brewing) it is usual to put the crystal malt into the mash tun along with the pale malt. This is done because the mash tun happens to be a convenient place to introduce it into the brewing process. It could just as effectively be added to the copper or boiled separately. Crystal malt should not comprise more than about 20 per cent of the total weight of grist in bitters or approximately 30 per cent in mild ales.

Chocolate malt

This is made by roasting high nitrogen malt in a kiln at temperatures of up to 230°C until the malt is the desired colour. The malt is then rapidly quenched to prevent further colour change. It provides a very pleasant characteristic flavour. It is a luscious dark coloured malt which finds application in porters, milds, and some bitters.

Black malt

This is made in much the same way as chocolate malt except that the darkening of the malt is allowed to proceed much further before the grain is quenched. The high temperatures involved destroy the enzymes and some °f the starch contained in the malt, therefore black malt has no diastatic activity and little fermentable extract. It is used to add flavour and colour to mild beers, porters, and stouts. The flavour imparted by dark malts is is similar to roast barley except that black malt is somewhat less dry. Black malt should not be used in high quantities else its flavour becomes overpowering. T here are various different grades of black malt, all imparting different flavour profiles.

Roast barley

Roast barley is unmalted barley that has been roasted in a kiln until it is burnt. It is again used to alter the colour and flavour of mild ales, porters, and stouts in particular. It has similar properties to black malt described above, except that the flavour imparted by roast barley, although similar, is much smoother and drier than black malt.

Being an unmalted grain it contains a high level of components that contribute to head formation and retention. It promotes a similar head to that of Guinness. Malt extract brewers can use roast barley without mashing. Like the dark malts, roast barley is used at quite low concentrations otherwise its flavour becomes overpowering.

Selecting, purchasing and using malts

All malts and some adjuncts need to be cracked or lightly crushed (milled) before use. Malt needs to be crushed to the correct degree it good extraction is to be achieved without impairing mash tun run off. It should be lightly cracked to expose the endosperm, not ground to a flour.

Amateur methods of crushing malt include coffee grinders, modified meat mincers, and a rolling pin and tea tray, I have yet to come across a method which crushes malt satisfactorily apart from a purpose built two-roller mill.

Fortunately all home-brew shops sell malt ready crushed, thereby saving us the difficulty of doing it ourserves. Malt, particularly in its crushed form, is hygroscopic and if not properly stored will absorb moisture from the atmosphere and quickly go slack. Ensure that the malt is in good condition if purchased ready milled, ensure that the grains are plump and that the endosperm is crisp but not hard, flinty or powdery. You should store crushed malt in a warm, dry place.

Malt extract

Malt extract are the mainstay of the home-brewing hobby. The majority of home brewers use malt extract as their basic source of fermentable sugars, and all ordinary beer kits are based upon malt extract. Malt extract brewing is quick and simple and there is no doubt that the home-brewing industry would not have grown to its current size had it not been for the availability of this product.

Malt extracts are produced by mashing malted barley in the conventional way and then concentrating the resaltant wort by passing it through a multi-stage low temperature vacuum evaporator until it is concentrated to about 80 per cent solids.

Malt extract should be made from the same high-qualitybrewing malt that would be demanded by the commercial brewing industry. Unfortunately, a lot of it is not! The majority of malt extract produced in this country is made for the food industry, and this finds its way into many of the cheaper beerkits and some of the not so cheap. The requirements for brewing-grade barley are almost completely the opposite to those for food-grade barley: unfortunately food-grade barley and cattle-feed barley is much cheaper.

One or two of the better malt extract manufacturers, particularly those that are maltsters and ptimarily supply the commercial brewing industry with malt and malt extract, now declare on their product packaging that their malt extract is made from the best quality brewing malt. It is a wise precaution to ensure that such declarations exist on any malt extract you purchase.

There are a whole range of malt extracts available; hopped, unhopped, mild flavoured, strong flavoured, light, medium or dark coloured, diastatic and non-diastatic. Malt extracts have a number of uses to the grain brewer; making yeast starters, as an additional source of fermentable extract, or as source of diastatic enzymes.

Dried malt extract is also available. This is produced by atomising ordinary malt extract by spraying it through nozzles at the top of a tall tower. As the mist drops down the inside of the tower it meets a counter-current of dry, filtered air, sometimes nitrogen, and the moisture is evaporated from the extract as it falls to earth. I do not rate dried malt extract very highly as a primary brewing ingredient, but it is particularly useful for yeast starters, priming solutions and similar purposes.

Diastatic malt extract

A Special type of malt extract is available, known as diastatic malt extract, which contains the diastatic enzymes necessary to convert additional starch into fermentable sugars, and is necessary for malt extract-based recipes which contain unmalted adjuncts in their formulation. In ordinary malt extracts these enzymes are destroyed by the high temperatures employed during the evaporation process. The best-known diastatic malt extract is EDME DMS (diastatic malt syrup), but Brewing Products Ltd have recently begun to supply a diastatic malt extract.

Diastatic malt-extract is a specialist product and its proper use involves a short mashing stage at 65°C followed by a wort boil. It must be used if the recipe calls for it, but is unnecessary otherwise. However, it seems to be a much misunderstood product. A large number of published recipes specify the stuff unnecessarily, and an alarmingly large number of recipes do not specify it when they should. In the latter case failure is sure to result. The proper application of diastatic malt extract is described elsewhere.

Malt adjuncts

For our purposes the term "malt adjunct" refers to grain, malted or unmalted, that is capable of producing fermentable extract in our wort but does not possess the enzymes necessary to effect the conversion of starch into fermentable sugars. Adjuncts draw upon enzymes supplied by the pale malt in the mash. All adjuncts must be mashed, alongside malted barley or some other source of enzymes such as diastatic malt extract in order to effect conversion. Strictly speaking, sugars, syrups, crystal malt, black malts, or roast barley, are not considered to be adjuncts because they do not need conversion by the enzymes contained in the pale malt.

The term "adjunct" is much misunderstood. For some reason, probably because it rhymes with "junk", many people have acquired the notion that all brewing adjuncts are inferior ingredients which are included in recipes purely for reasons of economy and therefore must be undesirable. It is true that some adjuncts will produce a small gain in economy but it is not really significant. Adjuncts are not used in very large quantities. Furthermore, these materials are manufactured and processed and, like malted barley, are not exactly given to the brewers free of charge.

In general, adjuncts are used to provide subtle changes in flavour or to improve the brewing process in one way or another. Apart from modifying the flavour of beers, adjuncts can assist the brewer in many ways; such as aiding mash tun run-off, assisting clearing, improving head retention, improving beer stability, and reducing protein haze.

Malt adjuncts must be used intelligently. In fact, if they are used in too high proportion they will often have the opposite effect to that desired and will degrade the beer, As a rule, the combined weight of adjuncts should not exceed about 20 per cent of the total weight of the grist. If adjuncts are used in too high a proportion problems soon begin to manifest themselves.

Mash tun run-off may be impaired due incorrect grist particle size, or due to too high a proportion of beta-glucan gums being extracted from unmalted grains. Mash tun conversion problems may occur due to a deficiency of the necessary enzymes, hazes may result due to a high proportion of undegraded protein being present, and yeast activity may be impaired due to a low level of assimilable nitrogen in the wort.

Torrefied grains, flakes, grits

Torrefied grains are grains that have been "popped" in a similar manner to pop-corn. The high temperature involved in popping explodes the endosperm of the grain and gelatinises the starch rendering it open to attack by the enzymes contained in the malted barley. Torrefied grains can be used in our mash tun directly without any form of pre-treatment.

Flakes are made by steaming the grain until it swells and then rolling it through heated rollers. The high temperatures destroy the aleurone layer and gelatinises the starch, rendering it open to attack by the enzymes contained in the malt. Flakes can be used in our mash tun directly without any form of pre-treatment.

Grits are unmalted grains that have been milled in a special manner to remove the germ and the nitrogenous outer layers of the endosperm. They are not used much by British breweries but are used widely by American and Australian breweries to dilute the high nitrogen content of their malts. They usually cannot be used in a mash tun directly. They need to be cooked first to gelatinise the starch. Continental and American breweries that use a high proportion of grits usually have a separate cereal cooker adjacent to the mash tun which is used to perform this gelatinisation process. The most common grit that we are likely to come across in British home brewing is rice.

Wheat flour

Brewers' wheat flour was probably the most commonly used adjunct in Britain; there was hardly a brewery in the country that did not use a proportion of wheat flour in its grist make up.

However, a couple of years ago the major manufacturer of brewers' wheat flour stopped making it, but this does not seem to have stopped a product called brewers' wheat flour being stocked by home-brew shops! Mind you, I have never been absolutely convinced that the stuff supplied in the shops ever was the genuine stuff. The wheat flour that I have seen used in breweries has always been in pellet form, whereas the stuff sold in home-brew shops is invariably a powder.

However, there are dozens of flour millers in the country and it is conceivable that other millers make the stuff. Most commercial brewers who were using wheat flour switched to using flaked wheat when it disappeared.

Brewers'wheat flour is made from special varieties of soft wheat which are high in glycoproteins and low in protein. The wheat is milled in a two-stage milling process similar to grits. The first stage removes the nitrogenous outer layers of the grain, and the second stage mills the degermed grain into a flour. The final stage uses an air centrifuge which separates a proportion of a controlled particle size which is low in protein. Wheat flour counteracts harshness in a beer, but its main benefit may not be apparent to the drinker. Its inclusion by the brewer improves head retention, and being low in nitrogen produces a beer with less haze potential. Typical proportions are between 5 and 10 per cent of the total weight of the grist. It has a similar extract to pale malt and in moderation can besubstituted directly for it. A possible disadvantage with wheat flour, particularly if used in too high a proportion, is that it can hinder mash tun run-off by blocking the filter bed of spent grains. When used in the British single infusion mash, wheat flour does not need to be cooked because its gelatinisation temperature is about 60°C. It can be put directly into the mash tun. Some brewers cook wheat flour to gelatinise the starch when they use a temperature programmed mash which has a low temperature protein rest period at about 50°C.

Malted wheat

Malted wheat has only recently gained in popularity in home brewing. It provides a rather unique wheat flavour to beers; much more pronounced than unmalted wheat flour. It is lovely stuff so beware! You will probably eat more of it than you use for brewing. Many continental breweries use high proportions of malted wheat in their wheat beers.

Raw barley

Raw barley has been used as an adjunct in the past, and was used by a number of breweries during the Second World War to try to combat malt shortages. Barley can be used at up to fifteen percent of the grist before serious problems begin to show themselves. Barley needs to be carefully milled so that the husk remains intact to provide adequate mash tun drainage, while the endosperm is adequately crushed to ensure efficient extraction, Barley brewing is best suited to the decoction mash, although it can be used carefully in the infusion mash. Interest in raw barley brewing has recently been revived due to the low cost of barley compared to malt and the availability of industrial enzymes. By using the decoction mash and adding enzymes to the mash. It is possible, although not recommended, to use up to seventy per cent raw barley in the grist.

Flaked barley

Flaked barley is another adjunct that is commonly used in both commercial and home brewing. It can be used in our mash tun directly. It imparts a grainy flavour to beers and it assists in head formation and retention. Like most unmalted grains, its use increases the risk of haze formation. It is quite a common ingredient in bitters, but it is used in higher proportions in dark milds and stouts where its rich grainy flavour is much appreciated.

Torrefied barley

Torrefied barley is grain that has been popped in a similar manner to pop-corn. This adjunct has not found a wide acceptance in home-brewing circles, probably because the flavour that it imparts is similar to that of flaked barley, although somewhat drier. Its inclusion in bitters and milds adds body and flavour and is therefore quite a valuable adjunct. Commercial brewers like to use a small amount of torrefied barley because it considerably aids mash tun run-off, preventing the goods setting firm.

Flaked maize

Maize (corn) is one of the earliest of malt adjuncts and world wide is probably the most widly used. Flaked maize imparts a characteristic corny flavour to bears and is useful in moderate quantities to give character and distinction to delicately flavoured beers. It is almost nitrogen free and is therefore useful as a nitrogen diluent.

Maize grits

Maize grits are a very predominate adjunct in Australian and American beers and is used by them in fairly high proportions, because it is a cheap method of diluting the high nitrogen con-tent of their malt, which would otherwise cause a protein haze. It imparts similar characteristics to the flakes above. Maize grits need to be cooked before use to gelatinise the starch. If small quantities are used it can be infusion mashed cooking, but if large proportions are used it should be decoction mashed or temperature-step mashed.

Flaked rice and rice grits

Flaked rice and rice grits are used in high proportions by Australian and American breweries but are not used much in this country. Rice is almost tasteless and colourless and is again a nitrogen diluent. Its main advantage is that it is cheap. It is also a colour diluent and is useful in producing the thin, very lightly coloured beers that are typical of American brewing practice. Flaked rice can be used directly in our mash tun, but grits will need cooking before use. Domestic rice is the easiest and cheapest source of rice. It can be used by first breaking the grain into a smaller particle size with a rolling pin, and then cooking by boiling in a small volume of water tor fifteen minutes before adding to the mash tun (complete with water).

Malted oats

Brewers located in hard water areas often used a proportion of crushed malted oats in their grist make-up (4 to 8 per cent) when brewing stouts or porter. It is said that the mellow flavour extracted from the oats counteracted the harshness induced by the hard water.

Oatmeal, rolled oats

It seems that unmalted oatmeal was used extensively as an economy measure during the war. Oats throw a haze, so its inclusion in any quantity was limited to dark beers and stouts, which at that time were the most popular beers. Oatmeal stouts became very popular, probably due to their supposedly nutritive benefit. They have only recently disappeared as a result of consumer protection acts.

Rolled oats of the Quaker porridge variety are the most cheaply available source of oats. They would be useful for producing Flemish-style wheat beers which use about ten per cent oats in their grist make-up, and they would no doubt be useful for counter-acting harshness in stouts brewed in hard water areas.

Barley syrup

It has always been the dream of brewers to bypass the maltster. Malted barley is more expensive than raw barley, so to deprive the maltster of his income would result in a considerable cost saving. Science has come to the aid of greed in the form of industrial enzymes. It is now possible to mash large quantities of raw barley by adding industrially produced enzymes to the mash. The enzymes manufacturers claim that up to seventy per cent raw barley can be used with no reduction in beer quality.

This is probably the closest thing to chemical brewing that I have come across. All of the important enzymes have to be supplied from elsewhere; alpha-amylase, beta-amylase, proteinase, and beta-glucanase all need to be added to the barley during the mash.

Surprise, surprise! Who should be foremost in the rush to cheat their customers and take advantage of this wonderful opportunity to increase their profits, but certain unscrupulous member of the British home-brewing industry. A number of beer kits have high proportions of cheap barley syrup included in their make-up, and also expect the home brewer to chuck in half a lorry load of cane sugar. This cheap practice simply makes a laughing-stock of British home brewers.

In my view, the only permissible application of barley syrup is as a priming sugar replace-ment, but there again, malt extract will do the job better.

Sugars

Commercial brewers have a bewildering array of brewing sugars available to them. All brewing sugars and special syrups are known as copper sugars, or copper syrups because they are added to the copper during the boil. They do not need mashing and are not added to the mash tun. They can be used with equal success in grain brewing or malt extract brewing.

There are many different types of sugar which are derived from a variety of materials. Some sugars are fermentable by brewers' yeast, but there are a number of sugars that the yeast is unable to ferment or can only ferment very slowly. In general, sugars derived from cane (or beet) are totally fermentable, whereas specialised brewing sugars that are derived from barley or maize contain a proportion of sugars that are non-fermentable, thereby imparting residual sweetness and body to our beer.

The subject of sugar is complicated due to the appallingly bad labelling on home-brew products. There are a number of products available in powder, liquid, and sticky-chip form that are spuriously labelled "brewing sugar", "glucose" or some other non-committal term. Very often it is not clear from the label what the product contained in the packet actually is. It could be one of a dozen types of commercial brewing sugar, all of which have different characteristics. It is further complicated by the fact that a packet labelled "Brewing Sugar" from one supplier may contain a completely different product to that of another supplier.

Ideally the label should specify the type of sugar, its fermentability, its Dextrose Equivalent number, and its EBC colour rating, so that there can be no confusion. All of these parameters are freely available from the primary manufacturers so there is no hardship involved in printing them on home-brewing product labels. It would certainly make my life easier when trying to devise repeatable recipes.

White cane sugar

White household sugar is the form of sugar most commonly used by home brewers although it is not used much in commercial brewing practice. Cane sugar (Sucrose) is a mixture of glucose and fructose bonded together molecularly. Brewer's yeast cannot ferment sucrose directly, so during fermentation it releases an enzyme Called invertase which breaks down the molecular bonds and splits sucrose into its component parts, ie, glucose, and fructose. Both glucose and fructose are easily fermentable by the yeast.

Cane sugar is totally fermentable and has the effect of drying and thinning a beer. It leaves no residual sweetness. If you want a sweeter beer, use more malt, less sugar. It is also a nitrogen diluent which makes it useful for reducing the risk of a protein haze forming in beer.

Sugar can be usefully employed to modify the characteristics of a beer, particularly if a fairly strong, drying beer is desired, but an excess of cane sugar will produce a particularly thin, char acterless beer. The best quality beers incorporate no sugar at all. Beet sugar is usually avoided by commercial breweries. It is said to encourage poor ferrmentation and ropiness (a bacterial infection), although I doubt very much if this is true with modern refining process. However. there is a perceivable optical difference between beet and cane sugars. A solution of cane sugar (Tate & Lyle) in water is absolutely colourless, whereas a solution of beet (Silver Spoon) has a slight yellowish tinge to it; so despite what the manufacturers say, there must be some differences between them.

Brown sugars

Brown sugars are very commonly used in home-brewing practice. They are the partially refined, unbleached brothers of white sugar. As a consequence of being partially refined they are darker in colour. When used in brewing they impart colour and, some say, a smooth, round flavour which is particularly valuable in milds, stouts, and brown ales. Brown sugar is available in several varieties, brown, soft brown, demerara, Barbados, etc. However, I suspect that there is little to be gained from using brown sugar over white.

Invert cane sugar

Brewers rarely use ordinary cane sugar, but instead use invert cane sugar. Cane sugar (sucrose) consists of equal parts of glucose and fructose which are bonded together moiecuiarly. Yeast can secrete an enzyme (invertase) which breaks these molecular bonds and splits the sugar into its two component types. Yeast needs to break these bonds and split sucrose into its component parts before it can ferment the sugars. Invert cane sugar is sucrose which has had the molecular bonds already broken by an industrial process. This saves the yeast the bother of producing the inversion enzyme, invertase, and therefore speeds up fermentation. Many brewers also feel that invertase can be tasted, produces a harsh "sugar tang", and causes disproportionate hangovers. Whether or not this is true is a matter of conjecture, but I can believe it.

There are various grades of invert sugar which are simply known as No.1, No.2, No.3, and No.4. They differ mostly in terms of the colour imparted; No.4 being the darkest. They are available from some home-brew suppliers, but are not popular because there is little to be gained over using cheaper domestic cane sugar, apart from the perceived side-effects mentioned above. Tate & Lyle Golden Syrup is a readily obtainable form of invert sugar, although an expensive way of buying it. Invert sugar, like ordinary sugar, is 100 per cent fermentable and leaves no residual sweetness or body in a beer.

Invert sugar has an extra molecule of water in its make-up and therefore gives a slightly lower extract than its non-inverted counterpart. If you are using commercial invert sugar you will need to use about fifteen per cent more than if you were using ordinary sugar.

Glucose powders, dextrose (dextrose monohydrate)

Glucose and dextrose mean much the same thing (but not the same thing as dextrins). Unfortunately, the term "glucose" has become a very euphemistic term and is used to broadly describe a whole range of sugars in both the food and brewing industries. The so-called glucose powder available from home-brew shops is unlikely to be pure glucose but a cereal derived sugar which is not 100 per cent glucose, and not 100 per cent fermentable. Indeed, not only is pure glucose quite expensive to produce, but it would offer no advantage to the brewer over using domestic cane sugar.

Again we are hindered here by the appallingly non-committal nature of home-brew product labelling. The actual fermentability of these products depends upon the manufacturing process employed; indeed, the manufacturers are capable of varying the fermentability at will. Some are manufactured by hydrolysing starch by acid treatment, and contain about 70 per cent glucose; while others are manufactured by the application of industrial enzymes and contain up to 85 per cent glucose. For practical purposes it is probably best to assume a fermentability of about 80 per cent unless the label states otherwise.

Maize syrups (glucose syrups / maltose syrups)

We are in a similar situation here to the glucose products mentioned above. Indeed the glucose and dextrose powders mentioned above are sometimes these products in crystaline form. There are a whole spectrum of maize syrups available commercially. The commercial brewing industry often simply calls them "glucose syrups", and the home brewing industry usually refer to them as "brewing sugar". Both are rather euphemistic terms which can hide a multitude of sins. The commercial brewing industry prefers to use the euphemism "glucose" because average "Mr. Public" is of the opinion that "sugar" is bad for you and makes you fat, whereas "gluose" provides energy and therefore must be okay. It saves the brewer from publicly confessing to using sugars or enzymically derived syrups. Certain confectionery manufacturers also use this misconception quite effectively in their advertising.

These syrups are usually produced from maize by means of Industrial enzymes, and are not simple sugars, ie, not pure glucose. They should more correctly be termed maize syrups. There are a whole range of maize syrups available, all of which contain differing proportions of glucose, maltose, and dextrins. We are again in the situation whereby we can never be sure exactly what is contained in the home-brew container.

For practical purposes these sugars can be considered to come in two basic types: high glucose and high maltose. The high glucose version contains about 40 per cent each of glucose and maltose and has about 80 per cent fermentability. The high maltose version is mostly maltose and has a fermentability of about 75 per cent. I tend to use the terms "maltose syrup" and "glucose syrup" to refer to the two basic types, but in practice it does not matter much which type is used. Apart from the small difference in fermentability the end result of using either type is about the same because glucose and maltose are readily fermented.

Maize syrups contain a proportion of non-fermentable sugars (dextrins); therefore the use of a maize syrup does not dry and thin the flavour of the beer as does the use of cane sugar. It is for this reason that commercial breweries prefer to use maize-derived syrups rather than cane sugar; it is more usual for breweries to use a maltose-rich syrup, rather than a glucose-rich syrup and allow the yeast enzymes to convert the maltose into glucose at its own rate. This apparently pleases the yeast. This is another series of products which the suppliers should print the Dextrose Equivalent number or the fermentability on the packaging.

Malto-dextrin (Burton Brew Body)

This cheeky product was introduced into home brewing to put the "body" back into beer kits! It is a wonderful idea: the industry sells beer kits that purposely have the body missing, and then they sell a product to put the body back. They would try to sell us dehydrated water if they could.

Malto-dextrin is a type of sugar, usually supplied in powder form, which is high in non-fermentable and slowly-fermentable dextrins, and is intended for adding body and slowly fermenting residual sugars to beers that are deficient in them. A low level of dextrin is only likely to manifest itself as a problem in cheap beer kits or beers which have too high a proportion of cane sugar in their make-up.

Malto-dextrin is manufactured from starch by the action of industrial enzymes; the source of starch usually being maize. The sugar spectrum of this product is determined by the primary manufacturers' specifications, and, like the maize products mentioned above, we have no way of knowing which manufacturer's product is thrown into our anonymous home-brew bags. As a guideline we can assume that the product will have about 35 per cent fermemability, leaving about 65 per cent residual dextrins to provide body. This is almost exactly the opposite to the sugar spectrum derived from malted barley.

The major legitimate use of this product is as a priming sugar replacement, where its high dextrin content may be useful in provided slowly-fermenting sugars to give the yeast something to chew on during long periods of maturation.

Lactose

Lactose is available from home-brew shops and is a form of sugar which is not fermentable by brewer's yeast and can therefore be used to sweeten beers. Lactose is milk sugar and is traditionally used to sweeten stouts, hence the old fashioned term "Milk Stout", now illegal under food labelling acts, and the reason for the picture of a milk churn on the Mackeson label. It can be added at just about any stage of the brewing process, but it is usually added along with priming sugars. H is best to dissolve it in boiling water first to ensure sterility. About 125 grams per 25 litre brew is a typical quantity.

Aspartame

The new, zero calorie, non-saccharin, diet sugars may also be useful for sweetening stouts or other beers. These sweeteners are usually based upon Aspartame, the best-known being Candarel. These sweeteners are again totally unfermentable, and supply nothing but sweetness. The preferred amount of sweetness imparted to any particular beer is obviously a matter of taste, but about 30 grams per 25 litre brew is a good starting point for a sweet stout. Again, these can be added at any stage in the brewing stage, but are usually added at the same time as priming sugars.

Caramel

Caramel is a substance derived from burnt sugar and is used in beer solely for colouring. Caramel should really have no place in the home brewer's armoury; we should not find it necessary to colour our beer.

The author of one home-brewing book offers the opinion that a good stout can be made from an ordinary beer plus the addition of caramel. The recipe he provides for a "good enough" stout is a very basic mild ale recipe into which is thrown a very generous helping of gravy browning!

If the man likes his beer in this way it is fine by me, but it certainly is not a stout, and it never will be. It is nothing other than a coloured mld ale. Many of us are home brewers because we expect considerably more than "good enough".

It is true that some breweries' milds, browns, and stouts are nothing other than light ales and bitters with caramel added, sometimes additionaly sweetened with lactose or priming sugars. We tend to follow commercial brewery practice in the home brewing field, but commercial brewery practice is by no means always good practice. It is interesting to note that the sales of these mediocre products, and the fortunes of the breweries concerned, have rapidly declined, whereas the sales of quality products have continued to thrive.

Guinness and Mackeson are very different beers, both are called stouts, both can be found in nearly every pub in the country irrespective of ownership. Both are famous all over the world and are available in over 60 different countries. Why do you think that this should be? I suspect that it is because they are not mediocre mild ales with a dollop of gravy browning added!

Recent EC restrictions on the use of caramel are being phased-in, and most breweries are being forced to cut back on the use of the stuff; some are even getting around to brewing their beers properly! There are new substitutes for brewers' caramel, and these will undoubtedly be used for colouring beer. Should you feel the need to colour your beer, some home-brew shops stock brewer's caramel. Liquid gravy browning is caramel, and can be used in an emergency.

Additional data

Tables 3.1 to 3.3 show typical parameters of major brewing ingredients. The ingredients are grouped in three classes, namely; primary brewing ingredients, adjuncts, and then copper sugars. The fermentability figures are typical, but approximate; mash conditions will affect the fermentability. Colour is shown so that non-British readers, who do not use terminology such as "pale malt", can identify the malts in question.

Table 3.1 Typical characteristics of mashed ingredients

Notes to table 3.1

The ingredients listed in table 3.1 are those which are normally put into the mash tun. The extracts in °kg/l are shown for the maximum possible extract which would be achieved in a laboratory, and a typical extract which would be expected in practice assuming a mash efficiency of 75 per cent. The fermentability figures are typical, but will vary according to mash conditions. It is not absolutely necessary to put crystal malt, black malt, or roast barley into the mash tun. They are included in table 3.1 because the mash tun is the normal place to introduce them. Malt extract brewers can simply put them into the copper and boil them along with the malt extract.

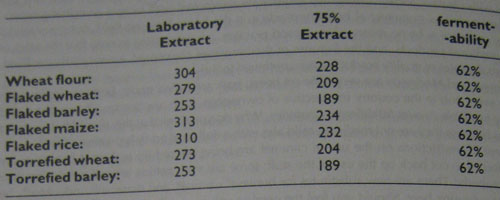

Table 3.2 Typical characteristics of malt adjuncts

Notes to table 3.2

All of the ingredients listed in table 3.2 are adjuncts and must be mashed alongside an ingredient that has a surplus of enzymes; such as lager malt, pale malt, mild ale malt, or diastatic malt extract The extract figures are in °kg/l.

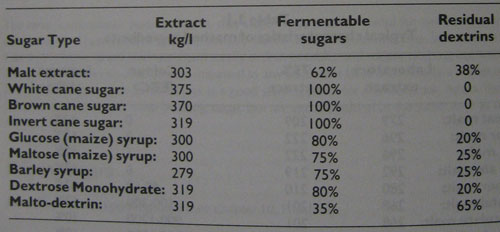

Table 3.3 Typical characteristics of copper sugars and syrups

Notes to table 3.3

Table 3.3 shows those sugars and syrups which are normally added to the copper, or added directly to the fermenter, or added to the cask as priming sugar. They do not need to be mashed and therefore the full laboratory extract is obtained. They can be used with equal success for all brewing methods whether brewing from malt extract or full-mash.

The percentage of fermentable sugars and non fermentable dextrins is also shown. The higher the fermentability the greater the amount of alcohol produced and the drier the beer will be. The higher the amount of dextrins the more body and flavour produced. The term residual dextrins has been used in a very broad sense. Most of these products contain some other non-fermentable bits and bobs which are not dextrins in the strict sense of the word.

Extraction rates

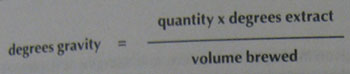

For every kilogram of grist mashed, or every kilogram of sugar added to the copper, a certain amount of soluble material is extracted from the goods and imparted to the wort to provide strength.

The extract provided by a particular ingredient is expressed by the units; brewers' degrees per kilogram litre (°kg/l) Tables 3.1 to 3.3 show the extract for the ingredients commonly employed in home brewing.

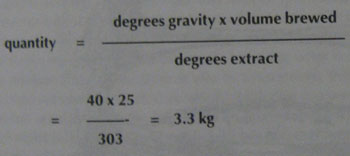

From table 3.3 it will be found that malt extract yields 303 °kg/l. This means that one litre of wort containing one kilogram of malt extract will have a gravity of 303 brewers' degrees; or, in other words, an OG of 1.303. This is expressed as:

Where:

Gravity is in degrees ie, OG 1045 = 45 degrees.

Quantity of ingredient in kilograms

Volume brewed in litres

Degrees extract of ingredient in °kg/l (from tables)

The quantity of malt extract required to produce 25 litres of beer at OG 1040 can be found thus:

The same technique can be applied to any ingredient. However, ingredients that are to be mashed are subject to mash efficiency because no matter how well we sparge there will always be some goodness trapped in the grains; we will never achieve the laboratory derived figures.

Tables 3.1 and 3.2 incorporate a second extraction rate column which shows the extraction expected at 75 per cent mash efficiency; which is about the lowest mash efficiency that we are likely to achieve. The 75 per cent column can be used instead of the laboratory extract in the above formulae and a mash efficiency of 75 per cent will automatically be taken into account.

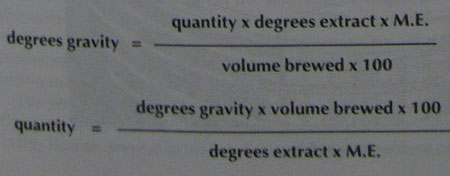

However, 75 per cent is an approximate minimum mash efficiency, chosen so that all brewers, novice or experienced, will achieve good results. An individual's personal mash efficiency will often be quite different, usually higher. The two formulas given above can be modified to incorporate personal mash efficiency, thus:

Where:

Gravity is in degrees ie, OG 1060 = 60 degrees.

Quantity of ingredient in kilograms

Volume brewed in litres

Degrees extract lab extract of ingredient °kg/l

M.E. is the mash efficiency in per cent.

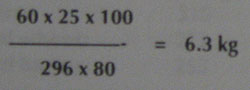

The quantity of pale malt required to produce 25 litres of beer at OG 1060 with a mash efficiency of 80 per cent is calculated thus:

Read also:

Traditional Commercial Brewing

Home Brewing. Beginners Start Here

Home Brewing. What should You Know about the Hops

All You should Know about Brewery Yeast